Chilly Temperature Concreting – Guidelines for Lesser Initiatives

Concreting in the winter season really should be gorgeous that time of yr, all that snow.

Sakrete

Whilst there have been many posts written about the problems involving all set-combined concrete when faced with cold weather conditions, this posting will aim on cold weather concreting suggestions and finest tactics for individuals scaled-down jobs utilizing bagged concrete or linked concrete maintenance resources. This can aid concrete contractors to use the ideal chilly-climate concreting safeguards and methods from the slide into the spring of any given year.

Cold Weather’s Consequences on Freshly Blended Concrete and Concrete Established Occasions

ACI 306R defines cold climate as a period of time when the average everyday temperature falls down below 40° F for much more than 3 consecutive days and the air temperature is not bigger than 50° F for extra than just one-fifty percent of any 24-hour cycle throughout the time period.

When drinking water and portland (hydraulic) cement are mixed, a chemical response takes place which releases warmth, recognized as the “heat of hydration”. This exothermic reaction places the environment of concrete in motion as effectively as the enhancement of concrete toughness, recognized as maturity. Reduced temperatures slow down the cement hydration method, resulting in delayed set times and lessened compressive energy of concrete at its previously ages.

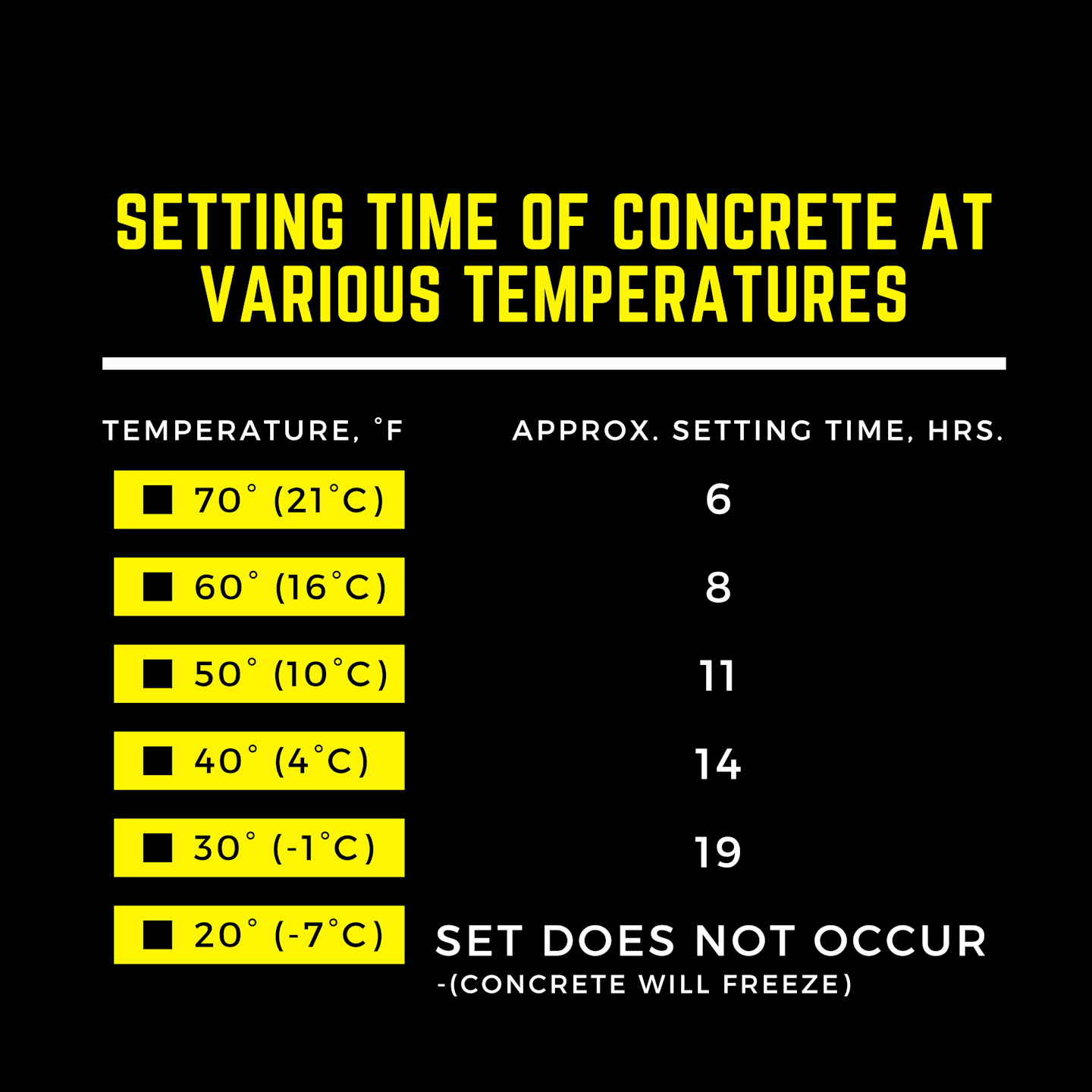

The approximate placing time for concrete raises as the temperature drops. System in advance.Sakrete

The approximate placing time for concrete raises as the temperature drops. System in advance.Sakrete

The optimal temperature for concrete is 70° F. We can see from this chart that when the temperature drops to 40° F, the set time much more than doubles from placement to remaining ending. Bear in mind that these scientific studies and studies, this kind of as the chart demonstrated above, reflect the placement of prepared-combined concrete throughout colder temperatures. There is a good deal far more mass in 1 cubic lawn of concrete as compared to the .6 cubic feet yield from an 80-pound bag of concrete blend. This implies there is a great deal a lot less heat generated when mixing bagged concrete as when compared to that poured from a all set-mixed concrete truck. Due to the smaller mass remaining positioned, a single must assume the established periods for bagged concrete placement to actually choose more time than the “Concrete Established Time and Temperature” chart implies in chilly climate.

Ahead of the Pour and Leading Up to the Placement

- Know the regional temperature forecast, noting the ambient air temperature, humidity, and wind speeds the working day of the task, and the 7-day weather conditions forecast adhering to the pour.

- Put together the subgrade, or prep the concrete to be fixed the working day right before placement and set the sorts.

- Protect the subgrade or spot to be repaired with insulating supplies to maintain the location and varieties heat. Eliminate the insulating components just in advance of the software of concrete or associated products.

- Select your winter mix and other products for the venture.

- Keep your products in a dry and heat conditioned area if feasible, as opposed to leaving the elements exposed on the work-website.

- Never ever pour concrete or use concrete mend elements on frozen ground or substrate, or if freezing temperatures will arise inside 48 hrs.

- Continue to keep an infrared thermometer helpful to look at surface area and materials temperatures.

- Above all, if the air temperature is too small or the location is experiencing significant inclement weather, hold off the placement.

Picking the Proper Blend for Chilly Temperature

As air temperature drops, so does the ground temperature. In the circumstance of a footing or publish gap, you have the soil surrounding the concrete to contemplate. When pouring a slab, the varieties and the stone foundation occur into enjoy. In these scenarios, the career-website aspects all soak up heat from the freshly mixed and placed concrete.

There are a few approaches to improve your “winter mix” to support increase warmth of hydration in colder temperatures. Both use a concrete bagged combine with a larger cement material, transform to a combine with a additional reactive, speedier-location cement, or both of those. To carry out this, consider upgrading to Sakrete 5000 Plus Concrete Blend for the greater cement written content or applying Sakrete Speedy Setting Concrete Blend for a speedier set.

For individuals heavier commercial or industrial jobs, or you want the most effective of both of those worlds, just take gain of the greater cement contents and unique cement blends like Sakrete Pro-X 180 Concrete Combine or Sakrete Pro-Blend Accelerated Concrete Combine.

Things to consider for Cold Climate Concrete Product Mixing

Deciding on the appropriate combine for chilly weather conditions will support the concrete to perform superior in lower temperatures, but it does not adjust the reality that it may perhaps even now be far too chilly to “jumpstart” the warmth of hydration. Right here are techniques to help create heat to get started the location process:

- When mixing concrete or fix materials, place at the least expensive slump doable, i.e. pour a drier combine. This is finished by only adding fewer h2o while mixing. Considerably less h2o usually means a decrease drinking water-to-cement ratio, which will shorten the established time of the concrete, reduce the bleed water on the surface area, and outcome in a more powerful, more durable concrete.

- Take into account incorporating a movement enhancing admixture to support lower back again on the drinking water, whilst assuring a looser and much easier to location blend.

- When location posts, utilize Sakrete Speedy Setting Concrete Mix in lieu of conventional concrete and basically blend the concrete before pouring into the gap.

- Use warm drinking water to mix the concrete. Heating h2o is the most sensible and least complicated usually means for raising concrete temperature. Very hot h2o from the tap usually does not exceed 120° F. This is adequate to warming the concrete adequate to carry about the cement hydration reaction. Do not include boiling water to concrete. This most possible will result in a flash established. Also, latex additives to repair service solutions or specialised concrete may perhaps melt at temperatures over 180° F.

- Calcium chloride is the most prevalent accelerating admixture. Hardly ever add more than 2% dosage by excess weight of cement. When using bagged concrete or concrete maintenance resources it is clever to purchase a premixed solution of calcium chloride, such as Sakrete C

ement Blend Accelerator, to help meter a correct dosage of the accelerator. Do not increase chloride-made up of accelerators to concrete that will contain steel reinforcement or that will satisfy metal. Chloride ions tremendously enhance the potential for corrosion. - Non-chloride, non-corrosive accelerators are an alternate to chloride accelerators. These are a lot less reactive than calcium chloride, but do not damage embedded reinforcement metals in the concrete. When arranging on working with a non-chloride accelerator with concrete repair elements or specialised, substantial general performance bagged concretes, blend a exam batch. Some non-chloride bases are not reactive with mixes containing a CSA cement.

- Hardly ever insert automotive antifreeze or windshield washer winter system to concrete. These products do not give “anti-freeze” attributes to concrete. That is a development fantasy and negatively impacts the longevity and top strength of the concrete.

Defense Just after the Pour

ACI 306.1-90 endorses preserving clean concrete from the elements for at the very least 3 days after placement, taken care of at 50°F. The stage is concrete can freeze just after placement. Concrete wants to be secured until eventually it reaches a bare minimum compressive power of 500 PSI [3.5 MPa]. Plastic concrete that freezes may possibly go through minimized toughness by 50% and its toughness will be adversely impacted.

Do not count on heat generated by cement hydration to secure new concrete from freezing. A calcium chloride accelerator is not a concrete anti-freeze.

Some simple methods for fresh concrete defense in the course of chilly climate are:

- Leave varieties in spot for 1 to 7 days, dependent on the severity of the cold climate adhering to the placement. This will help distribute heat evenly by way of the concrete.

- Immediately after the concrete is concluded, take into account applying membrane-forming curing compounds, these as Sakrete Concrete Treatment N’ Seal.

- Protect the floor with insulating resources this kind of as rigid board insulation, insulated curing blankets or tarps, or plastic sheeting included by straw. For the straw strategy, make positive to area a excellent 12-inches or extra layer of straw and best with a further sheet of plastic.

- For any of these insulating methods, recall to weigh down the best of the products to hold excessive drinking water out and the insulating components from blowing off the concrete.

- The exact same awareness to chilly weather security specified to slabs need to be supplied to slim sections of concrete or cementitious repairs, as thinner sections are extremely prone to freezing hurt.

- When the concrete matures, gradually take away the materials to stay away from thermal shock.

While chilly climate concrete placement poses its difficulties, if performed correctly, concrete placed at decreased temperatures will benefit from the slower curing situations. This results in a concrete that will produce larger final power and improved longevity.

If you are newer to concrete or only wish to know more about cold climate and the issues it poses for concrete, a great spot to begin is by looking through the American Concrete Institute Normal Suggested Exercise for Cold Temperature Concreting (ACI 306R).

Dirk Tharpe, Sakrete Concrete ExpertSakreteDirk Tharpe has used his qualified lifetime in the all set-combined concrete, masonry, and concrete restore goods industries. He at present operates with Oldcastle APG representing the Sakrete, Amerimix, and Belgard makes. Sakrete concrete, concrete repair, and mortars have the appropriate Pro-Quality solutions for any challenge and a committed crew of Technical Products and services Gurus to help. Oldcastle APG, a CRH organization, is a person of the leading companies of outside dwelling and constructing solutions. Oldcastle APG belongs to CRH’s Constructing Goods division. CRH is a main worldwide diversified building materials team, employing around 77,600 folks at above 3,100 functioning places in 31 international locations around the world.

Dirk Tharpe, Sakrete Concrete ExpertSakreteDirk Tharpe has used his qualified lifetime in the all set-combined concrete, masonry, and concrete restore goods industries. He at present operates with Oldcastle APG representing the Sakrete, Amerimix, and Belgard makes. Sakrete concrete, concrete repair, and mortars have the appropriate Pro-Quality solutions for any challenge and a committed crew of Technical Products and services Gurus to help. Oldcastle APG, a CRH organization, is a person of the leading companies of outside dwelling and constructing solutions. Oldcastle APG belongs to CRH’s Constructing Goods division. CRH is a main worldwide diversified building materials team, employing around 77,600 folks at above 3,100 functioning places in 31 international locations around the world.